Feel free to let this play in the background, It was a really informative conversation and I definitely learned a lot about how the subtractive manufacturing workflow functions on an industrial scale. So please, Enjoy!

Background

Alexander’s Machine Shop – Website

Allen Keith is a retired CNC instructor from A-State Newport, who now runs a machining facility with his son in law, daughter, and wife. I got in touch with him through the A-State Innovate program at a public makerspace here in town called the garage(which if you’re interested in and nearby you can check out my article on local CNC resources).

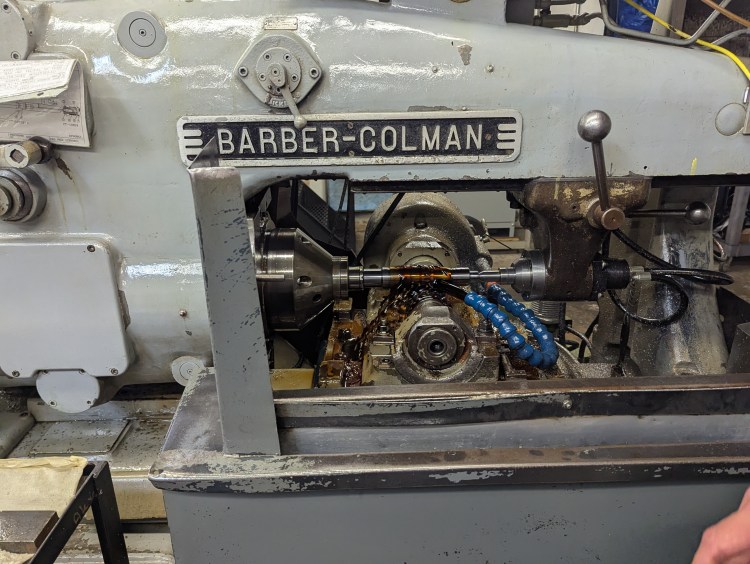

They gave me a tour of the facility and when I visited the part in production were splined drive shafts for PTO’s(Power Take Off, likely for a tractor). Below is a complete technical drawing of one that Alexander’s Machine Shop got from a client, the machinists here seperate this technical drawing into multiple sheets based on different machining operations. This allows the part to be passed between multiple machines during the manufacturing process.

I snapped some pictures while I was there and added them to this slideshow if you feel interested to click through them.

Allen’s advice to CNC and Engineering beginners

1st Go network,

– NEA Career and Tech Center like the Jonesboror Highschool has – NEACTC

-Or enroll yourself in a technical program that has access to industrial grade machinery – A-State machinist program

2nd: Know where and how how to find information and apply it

3rd: Stay motivated, engineering will keep your mind occupied

4th: Be flexible and open to broad experiences and perspectives