I got in contact with the local Maker Space on the A-state campus and talked to Michael Alexander, I asked him some questions about some 3D Printing, and this is our conversation .

The most important thing to remember in a new project?

Basically Just Stay focused on your goal, but it’s OK to change course if that’s what you need to do. Not all projects work out perfectly all the time, and so the more flexible and open to tweaks you can be, the more you’re going to be able to keep progress moving, even when things don’t go to plan the first round.

What’s a frequent error beginners have with 3D printers?

One of the biggest mistakes beginners make is diving right into printing really large or super complex prints with lots of pieces, straight out of the gate, Learn what your printer can do by beginning with smaller, simpler prints. Knowing how your settings effect the results will save a lot of frustration in the future

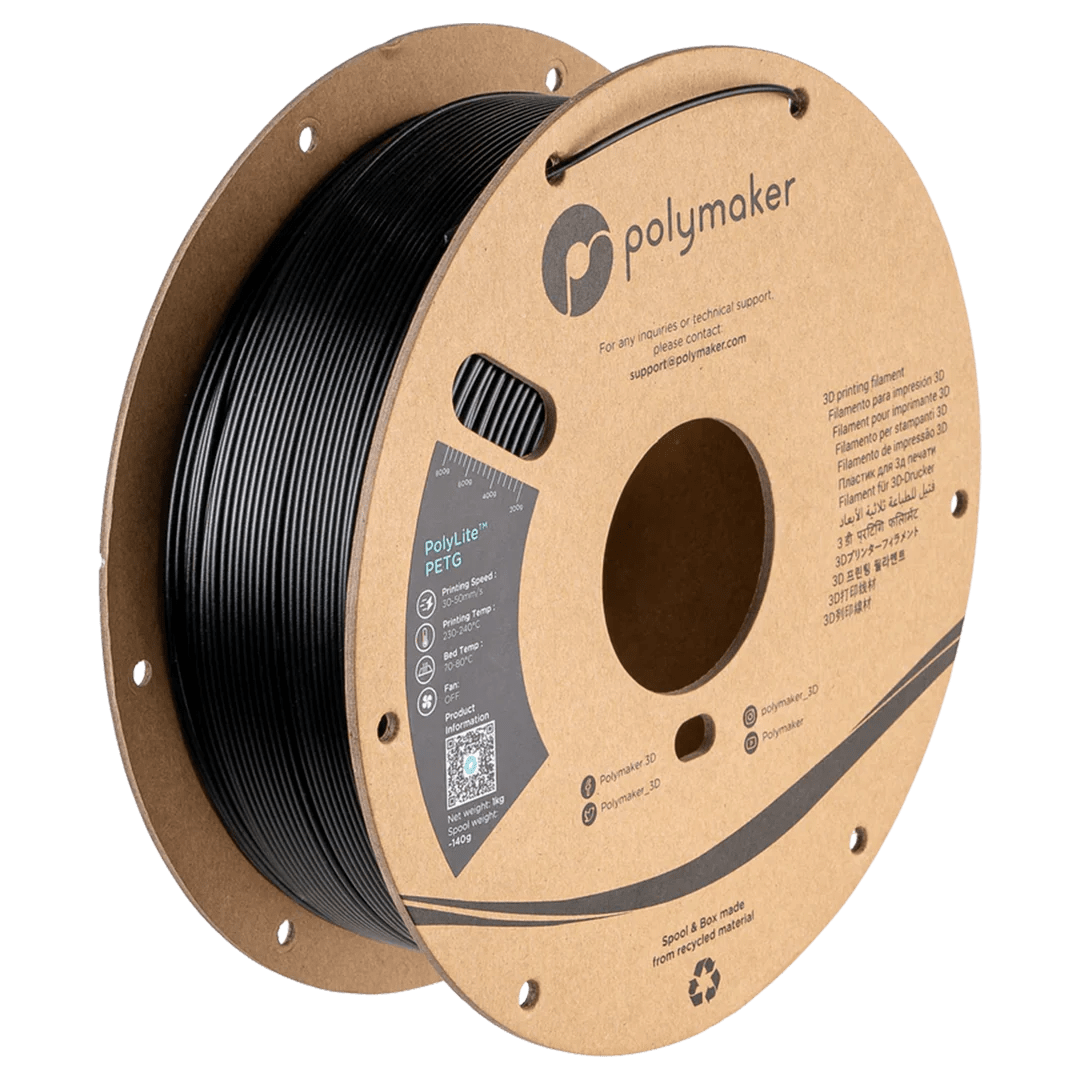

How do you choose which materials to use for each of your projects?

The material selection very much depends on the requirements of the project. For rapid prototypes, PLA is generally my go to because it’s handy and cheap. ABS or PETG is better for stronger or more durable prints.

What are some tips for makers who want to work on larger scale projects?

If it’s a bigger project, split it all into smaller pieces. Not only does it make it easier to print and assemble, it’s also helpful if something does go wrong, you just have to print or fix a section, not the whole thing. Also, when scaling up,

What’s a tool or software every maker should know?

For design, I suggest using Fusion 360. It is powerful and covers everything, from basic to complex work. And if you’re working with 3D printers, Bambu printers are a green flag, That’ll give you control and monitoring of prints and is really useful when you’re printing long jobs or multiple printers.